ARCHER Pop-Up Foam Sprinkler

The ARCHER Pop-up Foam Fire Sprinkler is specialised fit-for-purpose low-impact fire suppression technology designed to protect key aircraft hangar, apron & helipad / helideck infrastructure and the critical high-value aircraft assets and personnel within.

ARCHER Pop-up Foam Fire Sprinklers not only provide superior protection against the loss of life and/or asset (fire protection performance), but also provides superior mitigation against loss or interruption of just-as-valuable operations and function (recovery and system/facility operations & function continuity performance).

Pop-Up Sprinkler Activated

Pop-Up Sprinkler Ready/Normally Restracted

Loss of life/asset, nor interruption of operations & function, either is not an option. Critical operational & personnel sovereign defence & security (or commercial) capability is at stake, and protection of both: life & asset, and operations & function, is paramount. Protection of one at the mercy of the other compromises posture.

Whilst providing a high level of fire protection performance by way of deluge foam fire suppression capability, ARCHER Pop-up Foam Fire Sprinklers are a low-impact “low-level” “low-expansion” foam system installed in the area’s floor, and when operated, sprays firefighting foam low to the floor area only (including under-wing), is not destructive and has minimal impact on equipment and personnel within the environs of the hangar, including aircraft and their sophisticated avionics and components, ensuring the highest levels of recovery and system/facility operations & function continuity performance.

Compliance:

Complies with Defence MFPE

Complies with NFPA 11

Manufacturer’s Certificate of Conformance is available for each batch manufactured, including material certificates.

Unique and Superior Low-Impact Solution:

Excellent firefighting performance

Excellent recovery and system/facility operations & function continuity performance

Less detrimental effects of fire-fighting foam on aircraft avionics and components

Less downtime for clean up after discharge

Less water storage requirement

Less firefighting foam to be contained and disposed after a discharge

Minimises damage to aircrafts, people and equipment

Low level and discreet from floor level, (as opposed to traditional overhead system/foam sprinkler)

Typical Discreet Installation of ARCHER Pop-Up Foam Fire Sprinklers

Pop-Up Foam Sprinkler System in Action

Pop-Up Foam Fire Sprinkler Assy

Excellent Recovery and System/Facility Operations and Function

“Low-level” pop-up foam fire sprinkler systems are advantageous over other systems regarding the safety of life and assets such as:

Harsh powerful oscillating fire-fighting monitors/cannons/nozzles designed to blast large volumes of firefighting foam over large distances at high velocity.

& Overhead high-powered high- or medium-expansion foam deluge systems designed to non-discriminately flood/fill large voluminous spaces quickly, including foam flooding/covering and entering any equipment positioned therein.

Compared to both these solutions that when implemented in sensitive areas such as an aircraft hangar, cause high levels of collateral damage and can have devasting affects not only on the sensitive and sophisticated aircraft and associated equipment in their path of discharge, but also on the personnel within the environs at time of actuation, with the increased likelihood of personal injury, slips, trips, falls and disorientation, all impeding the ability to egress safely.

The ARCHER Foam Pop-Up Sprinkler are low-impact, non-destructive, “low-level”, “low-expansion” foam, which apart from its excellent firefighting performance, has excellent recovery and system/facility operations and function, due to it’s less detrimental effects on personnel and equipment.

Kind to Firefighters:

ARCHER Pop-up Foam Fire Sprinklers are also “kind” and low-impact on Firefighters. No need for Firefighters to:

“Duck and weave” an automated oscillating monitors’ powerful always-moving water foam jet cannon; or

Expose themselves and wade through deep, possibly over-head high, disorientating high-expansion foam, hiding trip hazards and other obstacles for firefighting hoses to be snagged on.

Safe and Low-Impact for Occupants, Firefighters and Equipment

Applications & Markets:

Aircraft Hangers

Helidecks

Aerospace

Defence

Large Asset Protection

Clients and Sites ARCHER has supported to date include:

HMAS Albatross (Nowra NSW)

RAAF Base Townsville (Townsville QLD)

RAAF Base Pearce (Bullsbrook WA)

Army Aviation Centre (Oakey QLD)

RAAF Base Edinburgh (Edinburgh SA)

RAAF Gingin Airfield Defence Avaiation (Gingin WA)

RAAF Base Amberley (Amberley QLD)

RAAF Base East Sale (East Sale VIC)

More….

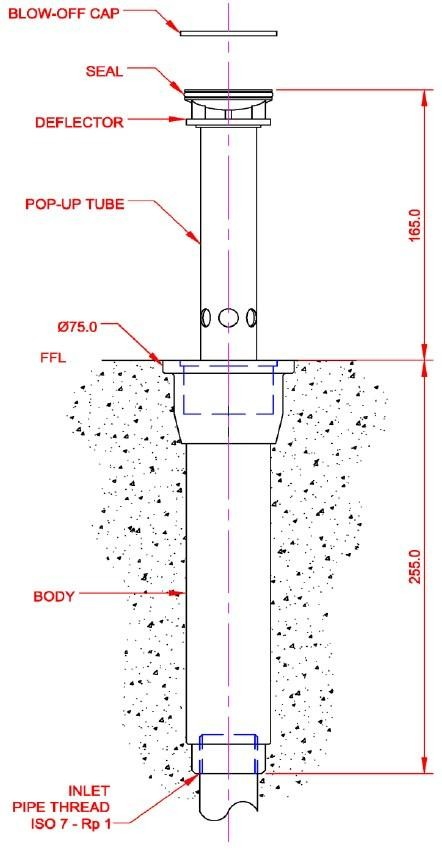

General Overview of the ARCHER Pop-Up Sprinkler Model AE12-450/1

Technical Data

Type: Aspirating, automatic pop-up type

Mounting: In floor

Discharge rate: 82 L/min @ 350 kPa

7.5 meter diameter @ 350 kPa

Spray pattern: 450 mm maximum height above floor

Min. operating pressure: 210 kPa

Inlet connection: Bottom entry, Pipe thread ISO 7 – Rp 1 (Female 1” (DN25) BSP Parallel)

Configuration:

Flanged top casting for flush mounting in concrete floor.

Fully retracting pop-up tube and deflector with a protective blow-off cap (standard colour signal red).

Body: 316 Stainless Steel

Outer Slide Tube: 316 Stainless Steel

Pop-Up Tube: 316 Stainless Steel

Seals: Nitrate

Deflector: 316 Stainless Steel

Blow-off Cap: 316 Stainless Steel (etch primed and sprayed standard colour signal red)

Total Assembly: 1.9kg

Flanged Body: 1.2kg

.

Accessories and Spares

AE12-007/8 Spanner (14-046-0049): For installation and removal of pop-up & outer slide tubes and deflector assembly.

AE12-007/7 (16-046-0044) Alignment and Pressure Test Plug: Recommended to be used during installation.

16-046-0075 Pull-Up Tool Assembly: To remove blow-off cap and perform pull test.

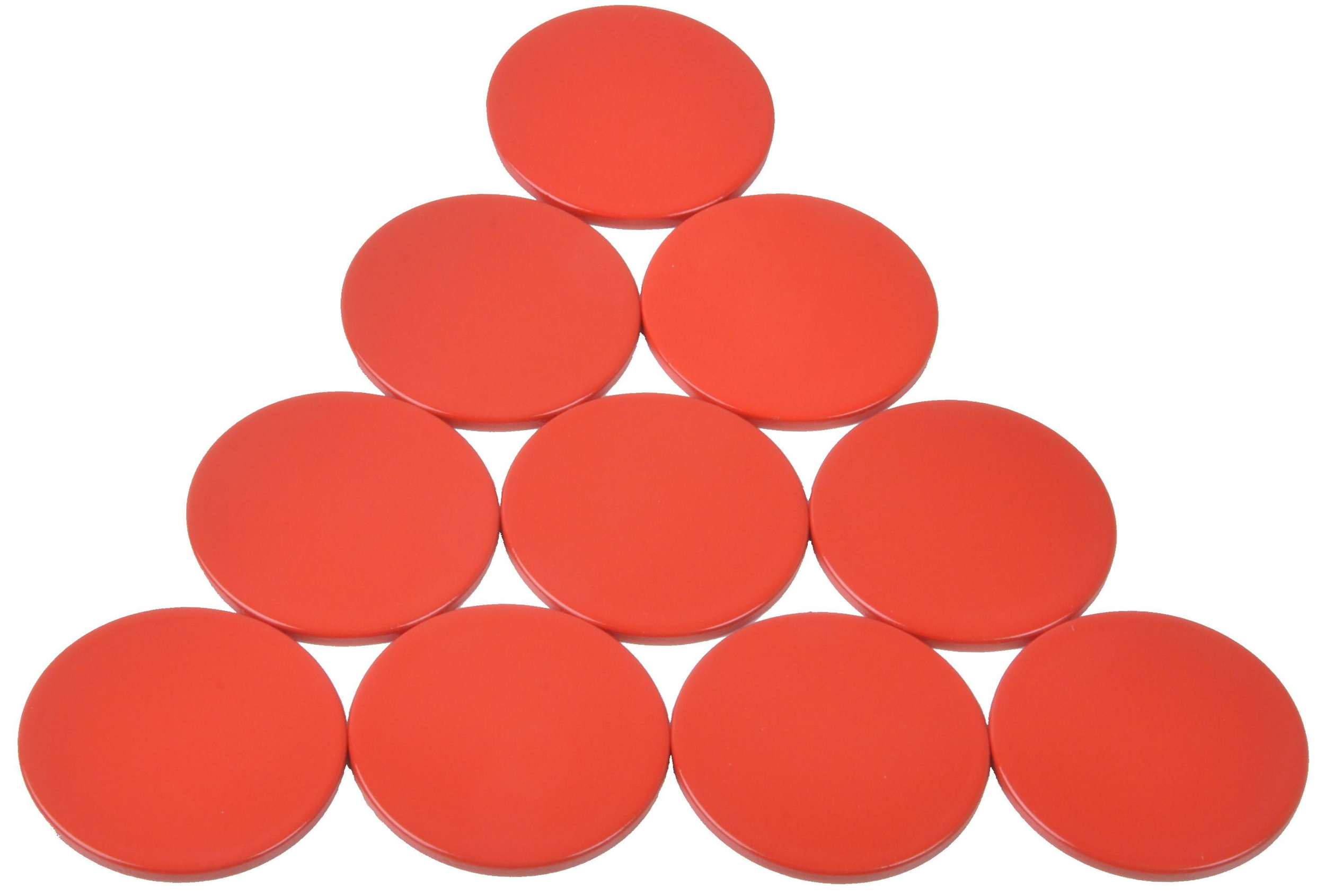

14-046-0077 Blow-Off Cap: Etch primed and sprayed standard colour Signal Red.

Spares Storage Cabinet: For housing Archer Model AE-12-007/1 or AE-12-450/1 Pop-Up Foam Sprinklers and accessories